- VALVE

- Product certification

- Trading area and Customer

- Supply Performance

- Heat storage material

Founded in Taiwan in 1985, STEMCO Group has been producing and delivering high quality industrial valves for more than 30 years at many sites around the world. Since 2018, we have expanded into various regions around the world by improving our sales capabilities and actively responded to our customers through our Korean branch.

HONEY COMB heat storage material is used in equipment to remove harmful substances by burning high temperature gases such as RTO, RCO, Scrubber and food waste incinerator at high temperature, so it must be resistant to thermal expansion and have excellent heat storage and adsorption.

HONEY COMB Heat storage material

Our products have a specific heat capacity of over 1000 J / kg·k and a maximum operating temperature of over 1700 ° C. They are used for reheating, heat storage of furnaces such as roasters,

soaking pit and cracking furnace. It can save more than 40% fuel, increase production by more than 15% and release flue gas temperature below 150 ° C.

This product is efficient in gas purification treatment stages of RTO and RCO plants, heat exchange and heat storage processes in industrial furnaces,

or filtration and purification units / packaging tower plants for gas and dust collection and purification.

Compared with conventional products, this product is effective in reducing system energy consumption.

All products and materials are made to individual customer needs and specifications.

Material of HONEY COMB heat storage

Alumina Ceramics

Alumina Ceramics is the most widely used advanced ceramic material. Owing to its highly strong ionic inter-atomic bonding, alumina offers good performance in terms of chemical and thermal stability, relatively good strength, thermal and electrical insulation characteristics at a reasonable price. With a range of purities and also the relatively low cost in raw material production it is possible to utilize alumina for wide ranging applications across a variety of different industries.

Silicon Carbide Ceramics

Silicon carbide is notable for its hardness, high melting-point and high thermal conductivity. It can retains its strength at temperature as high as 1400 °C and offers excellent wear resistance and thermal shock resistance. It has well-established and wide-spread industrial applications as catalyst supports and hot-gas or molten metal filters because of its low thermal-expansion coefficient and good thermal-shock resistance as well as excellent mechanical and chemical stability at elevated temperature environments.

Mullite Ceramics

Mullite occurs very rarely in nature because it only forms at high temperature, low pressure conditions, so as an industrial mineral, mullite has to be supplied by synthetic alternatives. Mullite is a strong candidate material for advanced ceramics in industrial process for its favourable thermal and mechanica properties: low thermal expansion, low thermal conductivity, excellent creep resistance, suitable high temperature strength and utstanding stability under harsh chemical environments.

Cordierite Ceramics

MCordierite has a superior thermal shock resistance due to their intrinsic low coefficient of thermal expansion (CET), coupled with relatively high refractoriness and high chemical stability. Therefore, it is often used as high temperature industrial applications, such as: heat exchangers for gas turbineengines; honeycomb-shaped catalyst carriers in automobile exhaust system.

Zirconia Oxide Ceramics

Ceramics Zirconia can be an ideal material of high-strength and high-toughness when proper compositions, such as: magnesium oxide (MgO), yttrium oxide, (Y2O3), or calcium oxide (CaO), are added to control an otherwise destructive phase transformation.The micro structural features of zirconia ceramics also make it an engineering material choice of wear and corrosion resistance, damage and degradation tolerance in a wide range of applications.

Corundum Ceramic

1. high purity: Al2O3> 99%, good chemical aaresistance

2. temperature resistance, long-term use aaat 1600 °C, 1800 °C short-term

3. thermal shock resistance and good aaresistance to crack

4. slip casting, high density, high purity aaalumina

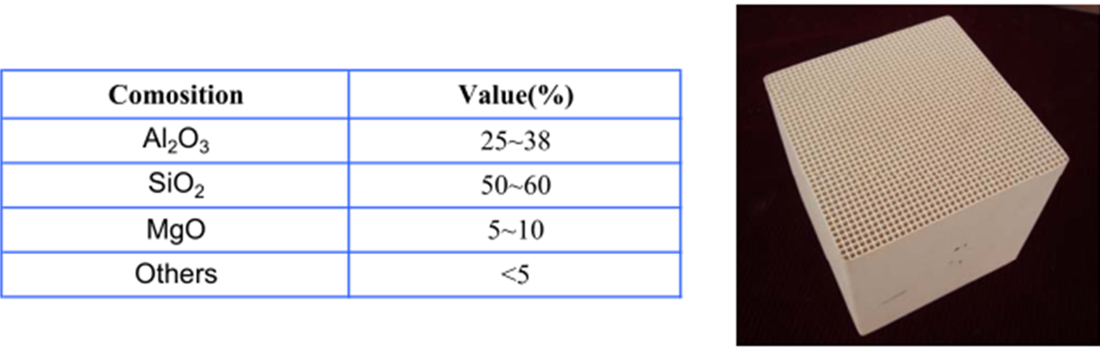

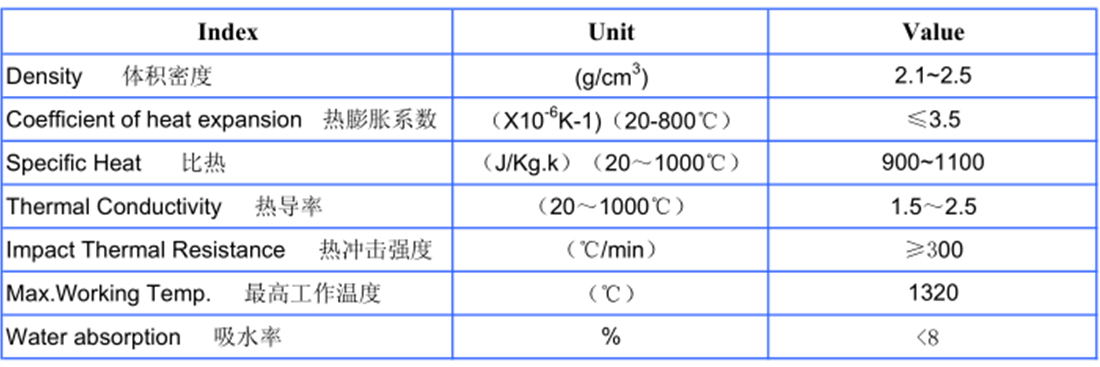

01. 多孔堇青石

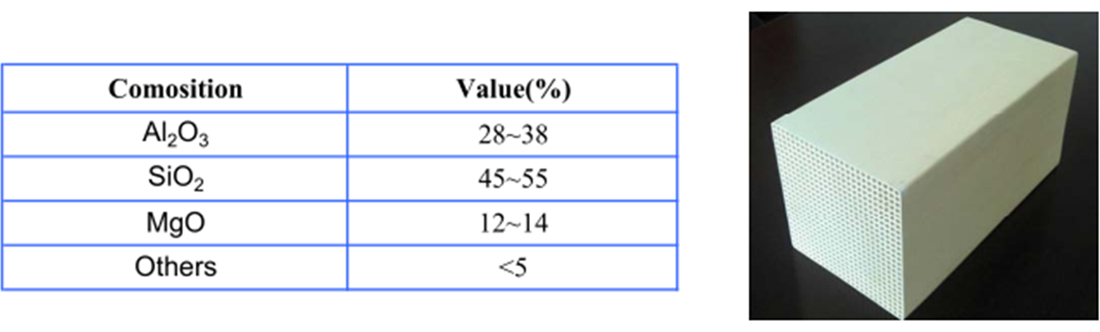

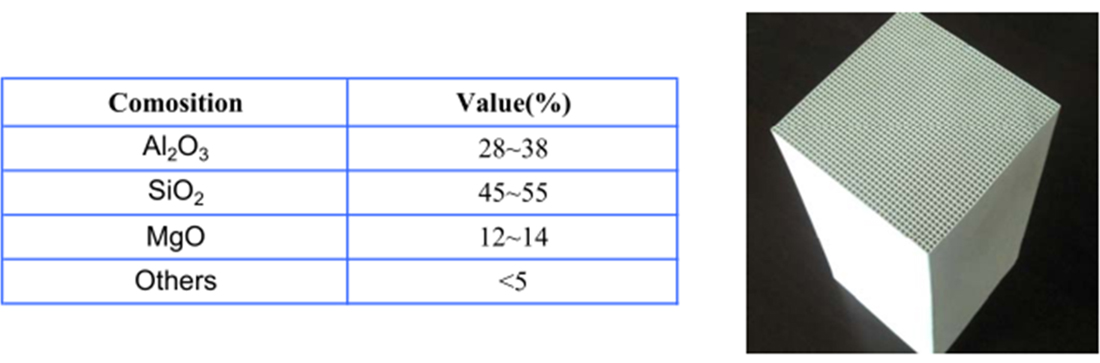

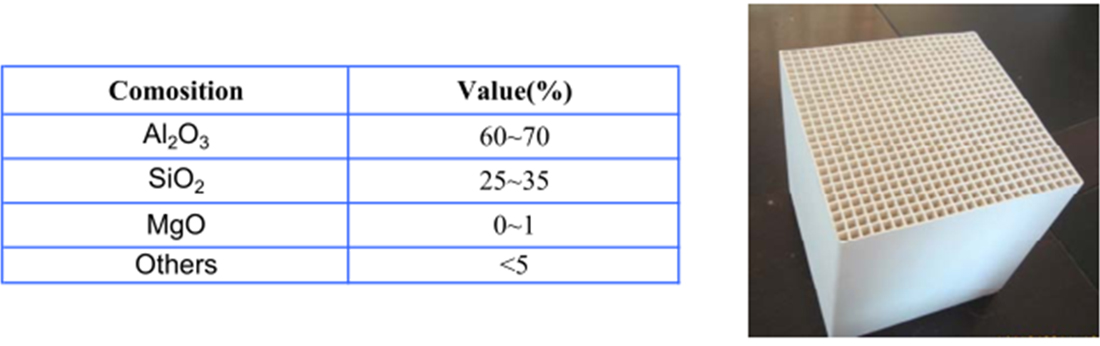

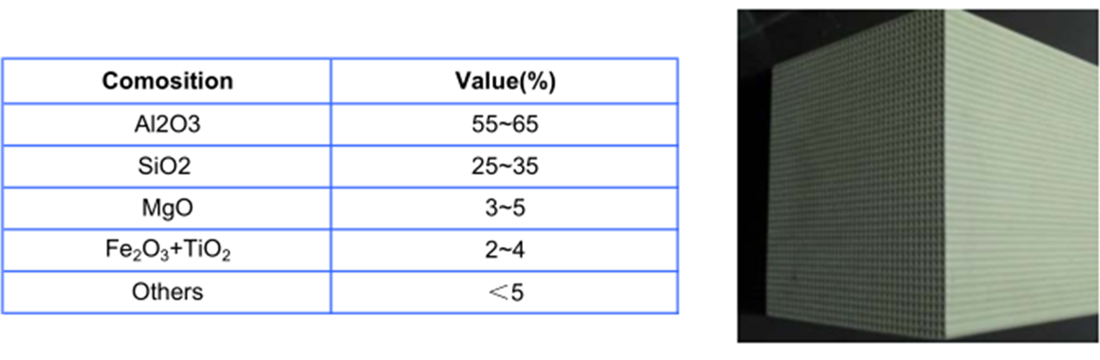

Chemical analysis

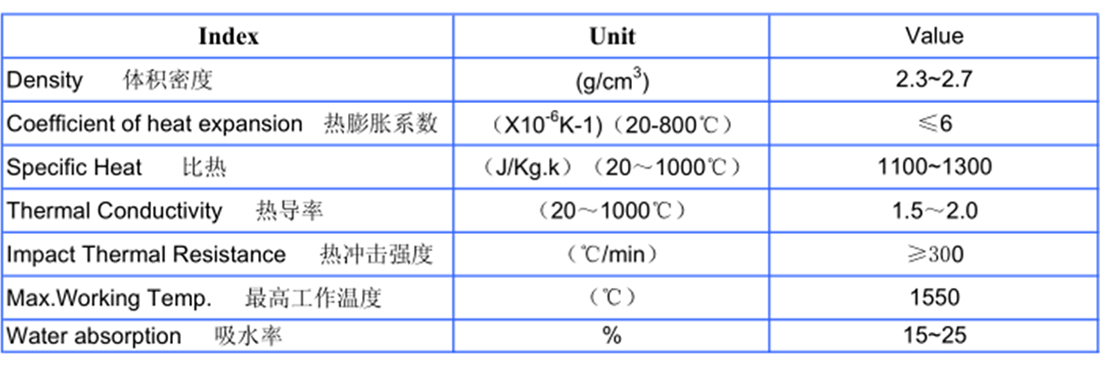

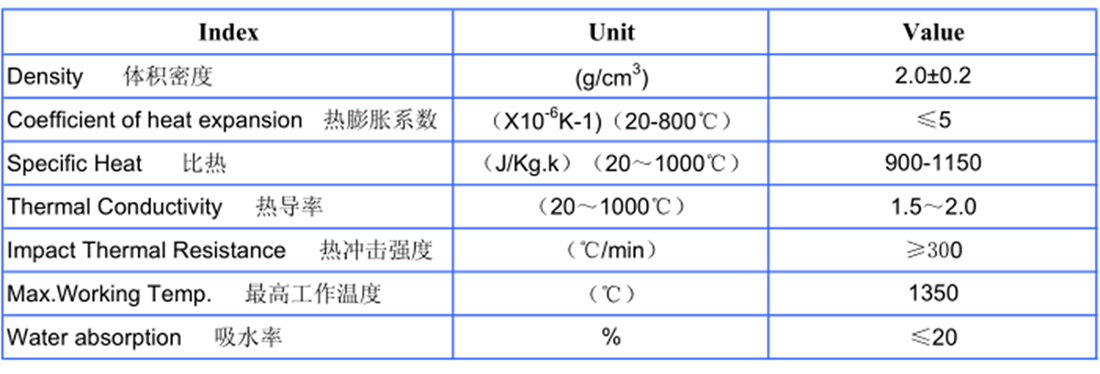

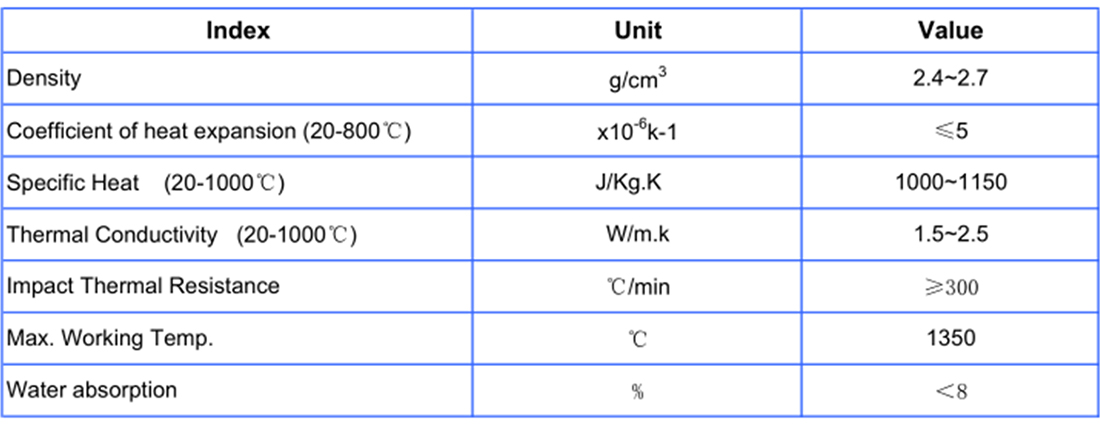

Physical properties

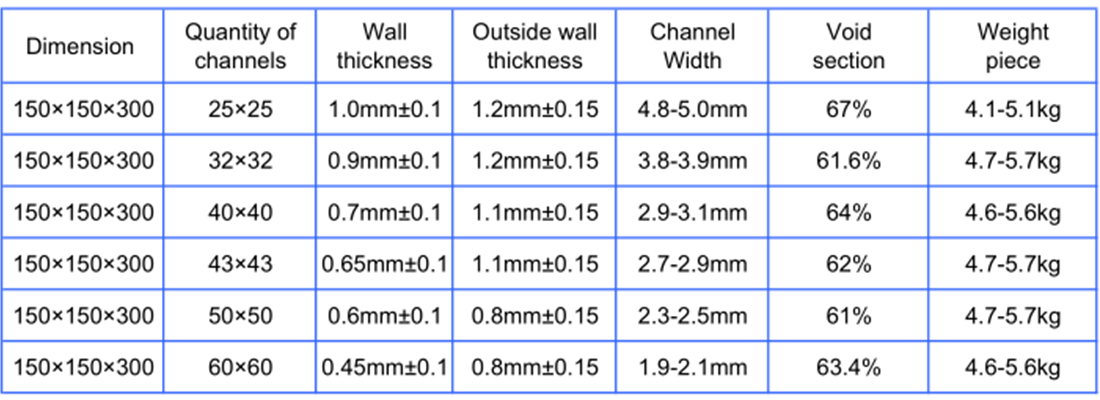

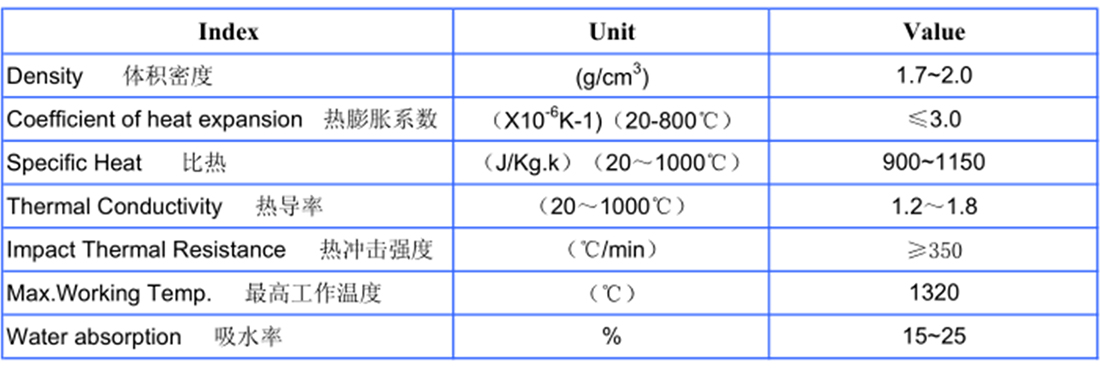

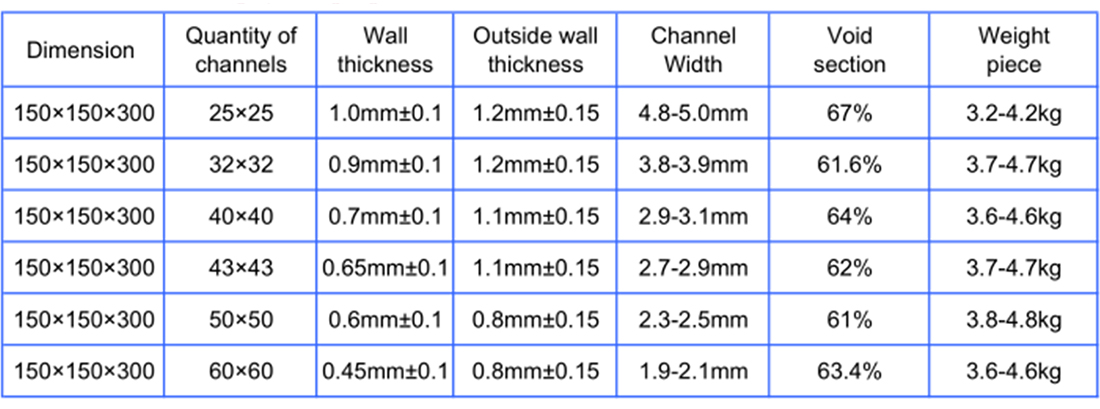

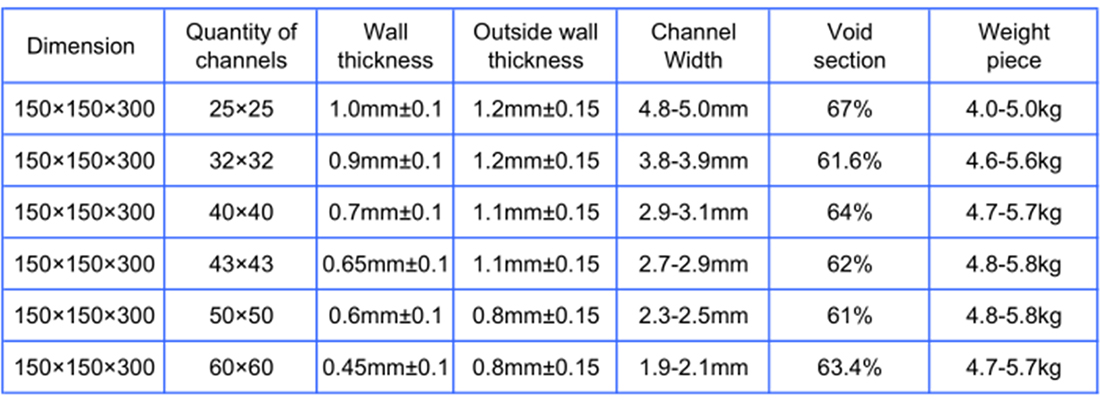

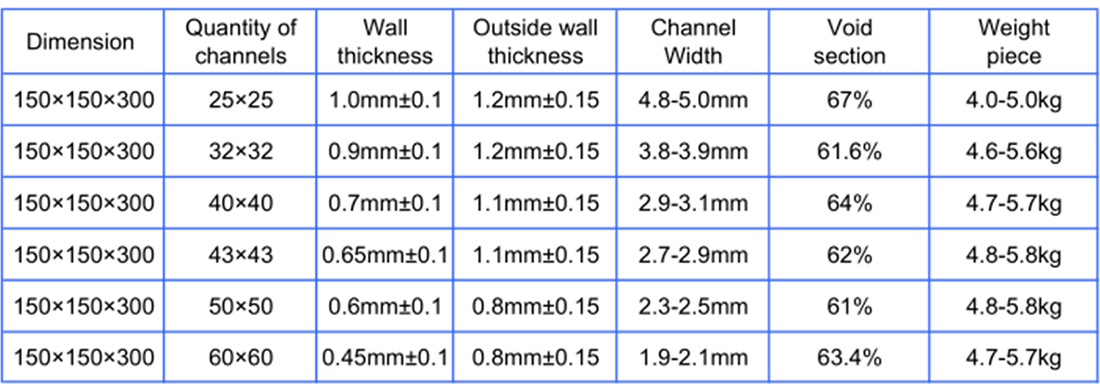

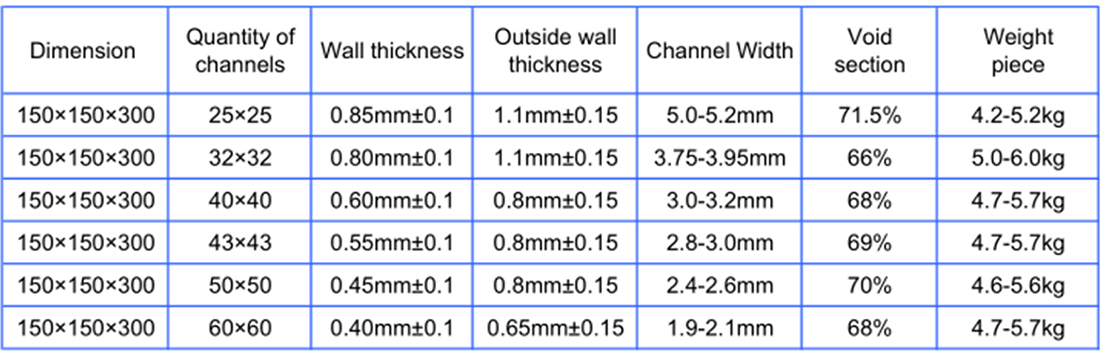

Dimentsion and other physical properties

02. 刚玉莫来石

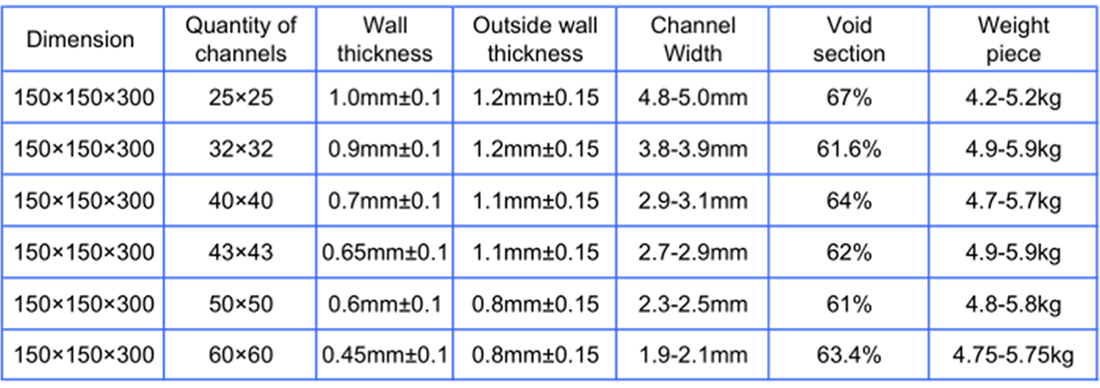

Chemical analysis

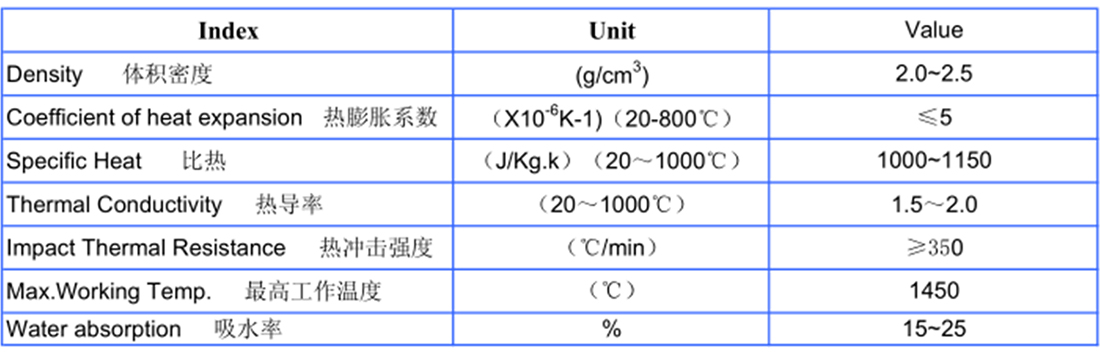

Physical properties

Dimentsion and other physical properties

03. 高铝

Chemical analysis

Physical properties

Dimentsion and other physical properties

04. 莫来石

Chemical analysis

Physical properties

Dimentsion and other physical properties

05. 致密高铝

Chemical analysis

Physical properties

Dimentsion and other physical properties

06. 致密堇青石

Chemical analysis

Physical properties

Dimentsion and other physical properties